What does it mean to have a flow meter that uses ultrasonic technology?

The action of a fluid flow on an ultrasonic beam (or ultrasonic pulse) is detected by an instrument known as an ultrasonic flow meter. This type of flow meter is used to measure flow. Doppler flow meters and ultrasonic flow meters are both names for the same thing. Because it is a volumetric flow meter, the liquid stream being measured needs to incorporate either air bubbles or very small particles in order for it to function properly. These meters are suitable for use with applications involving wastewater; however, you cannot use them with water that is fit for human consumption or water that has been distilled. Since this type of flow meter is chemically compatible, requires little maintenance, and has a low pressure drop, it is an excellent choice for applications that have these requirements. What exactly is it that the Doppler flow meter measures?

What exactly is it that the Doppler flow meter measures?

These meters have an impact not only on the acoustic properties of the liquid but also on its viscosity, density, temperature, and other characteristics in addition to those pertaining to its acoustic properties. In contrast to mechanical flow meters, these flow meters do not contain any moving parts and can measure flow rates accurately. Because the cost of these meters is very flexible, it is possible to utilize and maintain them at a cost that is lower than what might otherwise be required.

The fundamental idea behind how an ultrasonic flow meter works

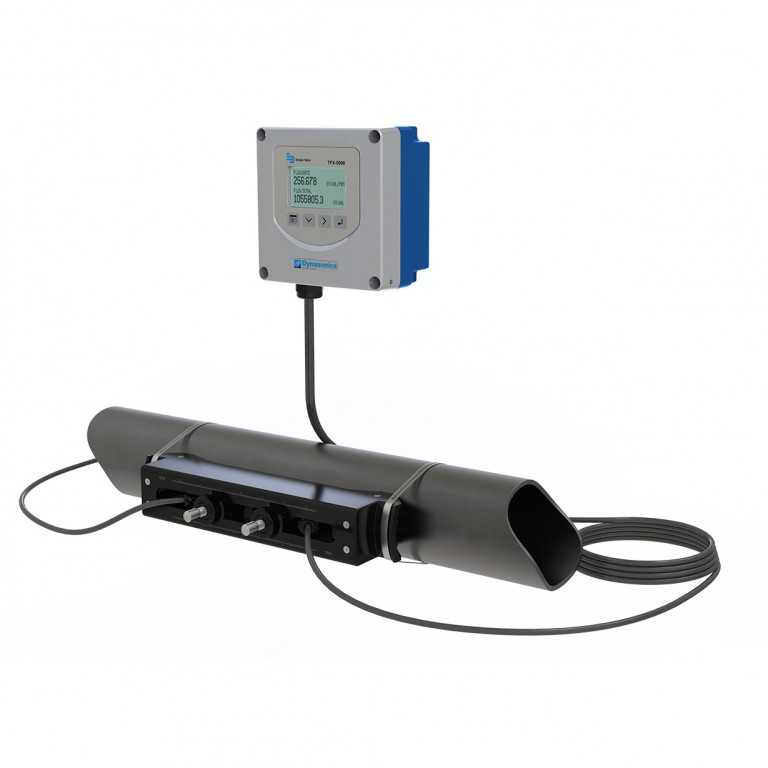

In order to successfully construct strap on ultrasonic flow meter, it is necessary to utilize upstream and downstream sensors, sensor pipes, and reflectors. Additionally, an ultrasonic flow meter must be calibrated. The primary means by which the ultrasonic flow meter communicates with the environment and uses sound waves to determine the speed at which liquid is moving through the pipe is by employing sound waves as its primary means of communication. Either there is no flow in the pipe, or there is flow in the pipe. These are the two possible outcomes. In the first scenario, the frequency of the ultrasonic waves is transmitted into the pipe, and the indication that is obtained from the fluid is the same. In the second scenario, the frequency of the wave that is reflected will be different. This is because the Doppler effect will be at play.

A linear increase in the frequency shift can be seen occurring whenever the fluid moves through the pipe at a faster rate. The flow rate is calculated based on the wave's reflection, and the transmitter is responsible for decoding the signal that the wave generates. The transmitter timer is the component that is accountable for sending and receiving ultrasonic waves in both the forward and reverse directions inside the pipe. When there is no flow, the flow time between the flow sensor upstream and the flow sensor downstream is the same. This occurs when there is no difference in their locations.

A representation in the form of a diagram of the internal workings of an ultrasonic flowmeter

The wave that is traveling upstream will progress at a slower rate than the wave that is traveling downstream, regardless of the conditions affecting the flow. As the liquid moves at a quicker rate, there will be a greater amount of time that passes between the occurrences that took place upstream and those that took place downstream. The transmitter performs calculations based on both the upstream and downstream times, which ultimately leads to the calculation of the flow rate. There is a diverse selection of ultrasonic flow meters available.

There is a diverse selection of ultrasonic flow meters available.

There are many different kinds of ultrasonic flow meters, but some of the most common ones are radar, doppler velocity, ultrasonic clamp-on, and ultrasonic level meters.

When determining the speed of a fluid, the primary method that Doppler velocity meters utilize is noise that has been reproduced using ultrasonic waves.

Radar-style meters make use of microwave technology to send out small pulses, which are then reflected back to the sensor from the flow surface below. This process allows the meters to determine the flow speed of the fluid being measured.

In conditions in which access to the pipe being measured is restricted or otherwise not possible, clip-on ultrasonic gauges are an excellent option for use as a measurement tool.

Since ultrasonic level gauges are capable of accurately measuring liquid levels, they can be utilized with either open or closed systems. This versatility makes their application possible.

Ultrasonic flowmeter: some of its most distinguishing features

It does not create any obstacles in the path that the liquid follows.

The o/p of the meter adjusts itself accordingly whenever there is a change in the density, temperature, or viscosity of the liquid that is being measured.

The movement of the liquid occurs simultaneously in both directions.

The meter provides a reliable response to varying levels of dynamic pressure.

The meter produces readings in an analog format at its output.

The principle of energy conservation

Appropriate for the monitoring of substantial quantities of mass flow

Installation and maintenance are both very easy to perform.

Very good versatility

Stay away from liquids in any and every way possible.

No risk of leakage

No moving parts, pressure loss

Excellent precision

This particular mechanical flow meter is quite pricey when compared to those that are available from other manufacturers.

The construction of the meter is very difficult to understand.

The audible features of this meter come with an additional purchase price.

These meters are relatively complicated in comparison to other meters; as a consequence, they can only be maintained and repaired by trained professionals who have received appropriate education.

It cannot measure cement that has rust on it or concrete pipes because of this limitation.

As soon as the pipe develops defects such as holes or air bubbles, it will no longer function as it should.

It is not possible to use it to measure pipes that are made of cement or concrete, or pipes that are lined with this material.