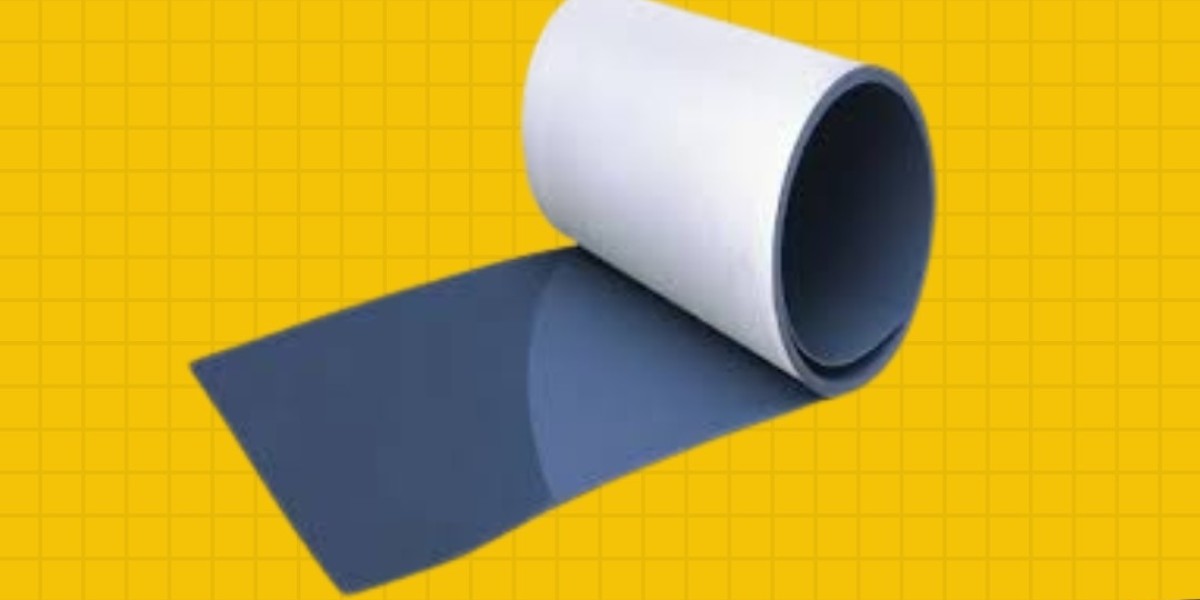

Polypropylene Glass Lined (PPGL) sheets, commonly referred to as glass liner sheets, are a cutting-edge material solution widely used in industries that demand superior surface protection and chemical resistance. Their ability to withstand harsh environmental conditions and corrosive agents makes them an essential choice for various industrial applications. In India, the demand for PPGL sheets has grown significantly due to their durability, versatility, and cost-effectiveness. This article delves into the features, benefits, and applications of PP Glass liner sheets, focusing on their role in providing unmatched surface protection.

Key Features of Glass Liner Sheets

Glass liner sheets are engineered to combine the robust properties of polypropylene with the strength of a glass lining. This hybrid design results in a material that is lightweight yet incredibly strong, making it ideal for industrial use. The key features of these sheets include high resistance to chemical reactions, low water absorption rates, and excellent mechanical strength. Unlike traditional materials, glass liner sheets are non-corrosive and do not degrade when exposed to acidic or alkaline substances, making them a preferred choice in chemical processing plants and wastewater treatment facilities.

Benefits of Using PPGL Sheets in India

The industrial landscape in India has seen a surge in the use of PPGL sheets due to their versatility and efficiency. One of the primary benefits of these sheets is their ability to protect surfaces from wear and tear caused by harsh chemicals and extreme temperatures. Additionally, PPGL sheets are cost-effective compared to other industrial-grade materials, making them a popular choice among lining sheet manufacturers in India. Their lightweight nature also reduces transportation and installation costs, further enhancing their value proposition for Indian industries.

Applications of PP Glass Lined Sheets in Harsh Environments

PP glass lined sheets are specifically designed to perform in harsh and demanding environments. They are commonly used in chemical industries for lining tanks, pipes, and reactors to prevent corrosion. Moreover, these sheets are utilized in the construction of industrial flooring and walls, where they provide a robust and protective layer against mechanical damage and chemical exposure. Industries such as food processing, pharmaceuticals, and textile manufacturing also rely on glass liner sheets to maintain hygienic and contamination-free environments.

How PPGL Sheets Outperform Traditional Materials

Compared to traditional materials such as metal or unlined plastic sheets, PPGL sheets offer superior performance and durability. Metals, for instance, are prone to rust and corrosion when exposed to moisture or chemicals, whereas glass liner sheets remain unaffected. Similarly, unlined plastic sheets may crack or warp under extreme conditions, but PPGL sheets retain their structural integrity. These characteristics make PPGL sheets the go-to material for industries that require long-lasting and reliable surface protection.

Role of Lining Sheet Manufacturers in Driving Innovation

Lining sheet manufacturers play a critical role in the development and availability of high-quality PPGL sheets. In India, manufacturers are investing in advanced technologies and innovative production methods to meet the growing demand for glass liner sheets. By adhering to stringent quality standards, these manufacturers ensure that the sheets are durable, reliable, and capable of meeting the specific requirements of various industries. The focus on sustainability and eco-friendliness in the manufacturing process also aligns with global trends, making Indian lining sheet manufacturers competitive on an international scale.

Installation and Maintenance of PPGL Sheets

One of the reasons for the popularity of PPGL sheets in India is their ease of installation and low maintenance requirements. These sheets can be cut, shaped, and installed with minimal effort, reducing downtime during industrial operations. Furthermore, the maintenance of glass liner sheets is straightforward; a simple cleaning routine is sufficient to keep them in optimal condition. This ease of maintenance contributes to their cost-effectiveness and enhances their appeal to industries looking for long-term solutions.

Customization Options for PP Glass Lined Sheets

Another significant advantage of PP glass lined sheets is their adaptability to various industrial needs. Lining sheet manufacturers in India offer a range of customization options, including different thicknesses, sizes, and surface finishes. This flexibility allows industries to select the most suitable PPGL sheets for their specific applications. Customization also ensures that the sheets meet the unique requirements of each project, further increasing their efficiency and effectiveness in protecting surfaces.

Environmental Benefits of Using PPGL Sheets

In addition to their functional benefits, PPGL sheets contribute to environmental sustainability. Unlike traditional materials that may degrade and release harmful substances, glass liner sheets are recyclable and have a longer lifespan. Their lightweight nature also reduces the carbon footprint associated with transportation and installation. By choosing PPGL sheets, industries can achieve their sustainability goals while benefiting from a high-performance material.

Challenges and Solutions in the Adoption of PPGL Sheets

While PPGL sheets offer numerous advantages, their adoption is not without challenges. One of the main hurdles is the initial cost, which may be higher than traditional materials. However, the long-term benefits of reduced maintenance and extended lifespan offset this cost, making PPGL sheets a cost-effective choice. Another challenge is the availability of skilled professionals for installation. To address this, lining sheet manufacturers in India are providing training and support services to ensure proper installation and maximize the performance of their products.

Future Prospects for PP Glass Lined Sheets in India

The future of PPGL sheets in India looks promising, driven by the increasing demand for durable and reliable industrial materials. With advancements in manufacturing technologies and a focus on innovation, the quality and performance of glass liner sheets are expected to improve further. Additionally, the growing awareness of the environmental benefits of PPGL sheets will likely boost their adoption across various industries. As India continues to develop its industrial infrastructure, PPGL sheets will play a vital role in ensuring long-lasting and efficient operations.

Conclusion: A Reliable Choice for Surface Protection

PP glass lined sheets have emerged as a superior solution for surface protection in harsh conditions. Their exceptional resistance to chemicals, durability, and adaptability make them an indispensable material for industries across India. By choosing PPGL sheets, businesses can ensure the longevity and reliability of their equipment and infrastructure while contributing to a more sustainable future. With the continued efforts of Lining sheet manufacturers, the potential of glass liner sheets in industrial applications is bound to grow, solidifying their position as a trusted choice for surface protection.

Frequently Asked Questions (FAQs)

1. What are PP Glass Liner Sheets?

PP Glass Liner Sheets are polypropylene sheets reinforced with a glass lining to provide superior strength, chemical resistance, and surface protection in harsh environments. They are used across various industries to protect surfaces from corrosion, wear, and damage.

2. What are the key features of PP Glass Liner Sheets?

Key features of PP Glass Liner Sheets include:

- High chemical resistance

- Non-corrosive and non-reactive surface

- Lightweight and easy to install

- Low water absorption

- High mechanical strength and durability

- Excellent performance in extreme temperatures

3. Where are PP Glass Liner Sheets commonly used?

These sheets are widely used in industries such as:

- Chemical processing

- Wastewater treatment

- Food and beverage manufacturing

- Pharmaceuticals

- Construction (industrial flooring, walls, and tanks)

- Textile and pulp processing