Request a Free Sample – https://www.procurementresource.com/production-cost-report-store/aluminium-nitrate/request-sample

Understanding Aluminium Nitrate and Its Applications

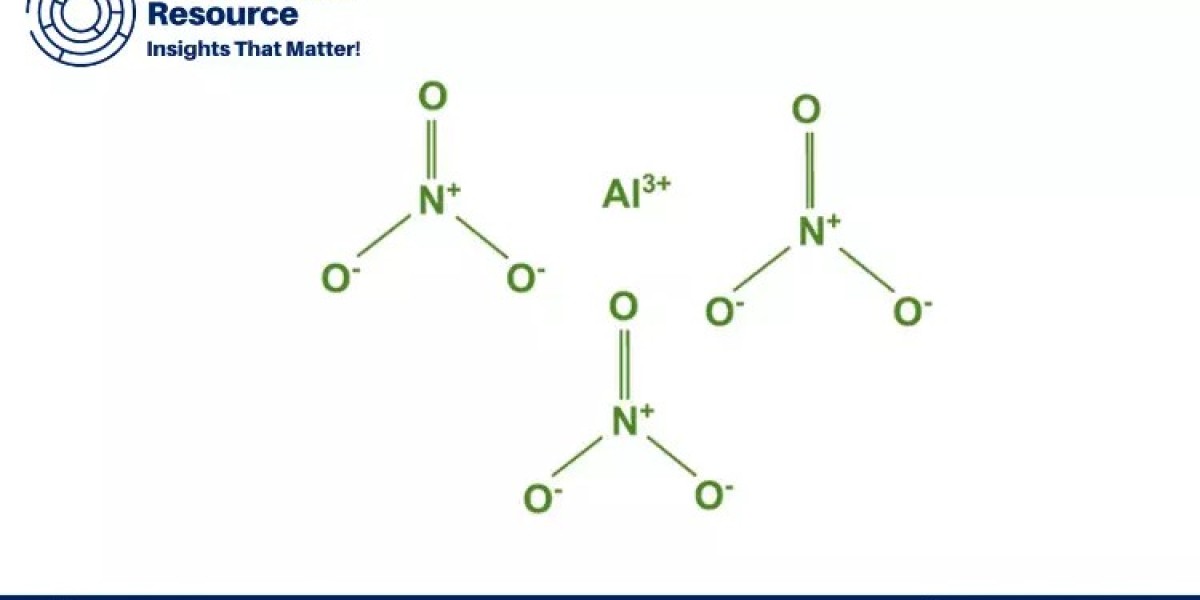

Aluminium nitrate, or aluminium trinitrate, is a chemical compound typically produced by the reaction of aluminium hydroxide or aluminium oxide with nitric acid. It is used in a variety of applications, most notably in water treatment, as a precursor to other chemicals, and in the production of speciality products like explosives and catalysts. The compound plays a vital role in purifying drinking water by neutralising contaminants, which makes it a crucial product in the global water treatment industry. Additionally, it is used in the production of aluminium salts, explosives, and in various chemical reactions.

Given its broad range of applications, the demand for aluminium nitrate is subject to fluctuations based on regional industrial growth, government regulations on water treatment and waste management, and the global expansion of the chemical and pharmaceutical sectors.

Aluminium Nitrate Production Cost: Key Factors

The Aluminium Nitrate Production Cost is influenced by several factors, including raw material costs, energy consumption, labor charges, and the cost of logistics and utilities. Each of these elements contributes to the overall production expenses, making it essential for manufacturers to optimise their operations to remain cost-effective while maintaining high-quality output. Below are some of the primary factors influencing the production cost of aluminium nitrate:

1. Raw Materials

The primary raw materials used in the production of aluminium nitrate are aluminium hydroxide or aluminium oxide and nitric acid. The cost of these raw materials can fluctuate depending on global supply and demand, geopolitical factors, and the availability of natural resources. Additionally, as aluminium ore extraction can be energy-intensive, energy costs also play a significant role in determining the overall cost of raw materials.

2. Energy Consumption

The process of producing aluminium nitrate is energy-intensive, as it requires high temperatures to react the raw materials. This means that the cost of energy, particularly electricity and natural gas, can significantly impact production costs. In regions with higher energy costs or limited access to low-cost energy sources, the production cost of aluminium nitrate can increase substantially.

3. Labor Charges

Labor charges represent a significant portion of the Aluminium Nitrate Production Cost. Skilled labor is required for managing the chemical processes involved in the production of aluminium nitrate. This includes overseeing the reaction between aluminium and nitric acid, controlling temperatures, and ensuring that safety protocols are followed. In addition to production staff, maintenance workers and quality control personnel are necessary to ensure the smooth operation of the plant.

4. Utilities and Infrastructure

Utilities such as water, steam, and compressed air are essential for the production process, adding to the overall cost. In areas where utilities are scarce or expensive, manufacturers may need to invest in on-site generation of water or power, further increasing production costs. Additionally, the infrastructure required for transporting raw materials, finished products, and by-products adds to the logistics costs.

5. Logistics and Supply Chain

The logistics involved in sourcing raw materials and distributing the final product play an important role in the overall cost structure. Transporting raw materials like aluminium hydroxide and nitric acid to the production plant, and then distributing the finished aluminium nitrate to customers, involves freight charges, warehousing, and inventory management. Companies must consider supply chain optimization strategies to reduce costs and ensure timely deliveries.

Extensive Aluminium Nitrate Production Cost Report: Cost Model and Pre-feasibility

A comprehensive Aluminium Nitrate Production Cost Report typically includes an in-depth cost model, pre-feasibility studies, and financial projections. These reports are crucial for businesses planning to enter the aluminium nitrate production market, as they help identify potential risks and opportunities.

Cost Model

The cost model provides a breakdown of all costs associated with the production of aluminium nitrate. This typically includes:

- Raw material costs: Breakdown of costs for aluminium hydroxide or aluminium oxide and nitric acid.

- Energy costs: Estimation of electricity, gas, and other fuel expenses.

- Labor costs: Salary estimates for production staff, supervisors, and maintenance workers.

- Utility costs: Water, steam, and other necessary utilities for the production process.

- Logistics costs: Transport costs for raw materials and finished goods.

Pre-feasibility Studies

Pre-feasibility studies are conducted to assess the viability of setting up a manufacturing plant. These studies help businesses evaluate the required investment, expected return on investment (ROI), production capacity, and market demand. A detailed pre-feasibility report will also cover potential risks, regulatory compliance, and environmental considerations, all of which can influence the overall production cost and profitability.

Industrial Trends and Supply Chain Considerations

The Aluminium Nitrate Production Cost is influenced by broader industrial trends and supply chain dynamics. Some of the most significant trends affecting production costs include:

1. Increased Demand for Water Treatment

As water scarcity and contamination become more pressing global issues, the demand for water treatment chemicals like aluminium nitrate is expected to rise. This increased demand can drive up raw material costs and logistics expenses, which, in turn, affects production costs.

2. Advancements in Production Technology

Technological advancements in production processes, such as more energy-efficient reactors or automated systems, can help reduce production costs in the long run. However, these technologies often require a significant initial investment, which may not be feasible for all manufacturers.

3. Regulatory Pressures and Sustainability

Governments worldwide are increasingly enforcing stricter regulations on industrial processes, particularly in relation to environmental sustainability. These regulations can add compliance costs, including investments in emissions reduction technologies or waste treatment systems.

4. Global Supply Chain Disruptions

Recent disruptions in global supply chains, caused by factors such as the COVID-19 pandemic or geopolitical tensions, have impacted the availability and cost of raw materials and transportation. Manufacturers must consider these disruptions in their long-term planning to mitigate risks and control costs.

Request for Real-Time Prices

If you're interested in accessing up-to-date pricing information on Aluminium Nitrate Production Cost, please request a free sample of our detailed market report. This will provide you with the latest data on aluminium nitrate pricing trends, cost breakdowns, and forecasts for the coming years.

For more detailed information or to request Free Sample - https://www.procurementresource.com/production-cost-report-store/aluminium-nitrate/request-sample

Procurement Resources

For businesses looking to source high-quality raw materials at competitive prices, procurement plays a crucial role in maintaining profitability. Partnering with reliable suppliers of aluminium hydroxide, nitric acid, and other key ingredients is vital to ensuring a smooth production process. Using effective procurement strategies, such as bulk purchasing and long-term contracts, can help reduce material costs and safeguard against price fluctuations.

By leveraging procurement resources and optimizing supply chain management, businesses can ensure cost-effective production while maintaining the quality and consistency of their aluminium nitrate output.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA