Introduction

In the rapidly expanding global market for plastics, the production of plastic granules plays a crucial role in providing the raw material for a wide array of industries. Plastic granules, also known as plastic pellets or resin pellets, are the basic building blocks used in the production of plastic products. These granules are created by melting and shaping various types of plastic polymers, which are then cooled and cut into small, uniform granules that are easy to handle, transport, and use in injection molding, extrusion, and other manufacturing processes. A Plastic Granules Manufacturing Plant Project Report provides a comprehensive guide for entrepreneurs, investors, and business professionals looking to establish a facility for producing plastic granules. The report covers market demand, raw materials, production processes, necessary equipment, financial projections, and operational requirements, offering detailed insights into setting up and running a successful plastic granules manufacturing plant.

Market Demand for Plastic Granules

1. Growth of the Packaging Industry

The global packaging industry is one of the largest consumers of plastic granules, especially in the production of bottles, containers, bags, and films. As the demand for packaged goods increases, driven by consumerism and online shopping, the demand for plastic products, and consequently plastic granules, continues to rise. Packaging materials made from plastic are lightweight, durable, and cost-effective, which makes them the preferred choice for many manufacturers.

2. Automotive and Electronics Manufacturing

Plastic granules are widely used in the automotive and electronics industries for producing components such as dashboards, bumpers, switches, housings, and cables. As these industries continue to expand globally, the demand for high-quality plastic granules for injection molding and other processes is also growing.

Get a Free Sample Report with Table of Contents@

3. Rising Demand in Consumer Goods

Consumer goods such as household appliances, toys, and furniture are increasingly made from plastics. Plastic granules are essential in the production of these goods, and the continued demand for affordable, durable, and aesthetically pleasing products ensures a steady market for plastic granules.

4. Sustainability and Recycling

With a growing emphasis on sustainability and environmental responsibility, many companies are shifting toward using recycled plastic in their products. This has led to an increased demand for recycled plastic granules, particularly for use in the production of packaging materials, textiles, and even automotive components. The development of eco-friendly materials and technologies, such as biodegradable plastics, also supports market growth.

5. Advancements in Manufacturing Techniques

Technological advancements in the plastics industry, such as improved recycling techniques and new polymer blends, are driving the demand for high-quality plastic granules. As manufacturers adopt more sophisticated processes for creating plastics with enhanced properties—such as improved strength, flexibility, or heat resistance—the need for specialized plastic granules has grown.

Types of Plastic Granules

Plastic granules come in a wide range of types, depending on the polymer used and the desired application. Some of the most common types include:

1. Polyethylene (PE) Granules

Polyethylene is one of the most widely used plastics globally. PE granules are commonly used in the production of films, bags, bottles, and containers. These granules are known for their flexibility, durability, and chemical resistance.

2. Polypropylene (PP) Granules

Polypropylene granules are used in applications requiring rigidity, such as automotive parts, textiles, and packaging. PP granules are highly resistant to chemical damage and are commonly used in food packaging, medical products, and containers.

3. Polyvinyl Chloride (PVC) Granules

PVC granules are used extensively in construction, healthcare, and automotive industries for manufacturing pipes, profiles, flooring, and medical tubing. PVC is known for its durability, fire resistance, and cost-effectiveness.

4. Acrylonitrile Butadiene Styrene (ABS) Granules

ABS granules are used in the production of rigid products that require strength and toughness. ABS is commonly used in the automotive industry, toys, and electronic housings.

5. Polystyrene (PS) Granules

Polystyrene granules are used in the production of disposable cutlery, packaging, and toys. These granules are lightweight, cost-effective, and offer a high degree of transparency.

6. Recycled Plastic Granules

Recycled plastic granules are made from post-consumer or post-industrial waste, and they are gaining popularity due to increasing awareness about sustainability and environmental impact. These granules are used in many applications, such as packaging, textiles, and automotive components.

Manufacturing Process for Plastic Granules

The production of plastic granules involves several key stages, from raw material procurement to the final granule formation. Below is an overview of the typical manufacturing process:

1. Raw Material Sourcing

The first step in the plastic granules manufacturing process is sourcing the raw materials, which include different types of polymer resins. These resins are usually purchased in bulk from suppliers and come in the form of powder, pellets, or small beads.

2. Plasticization

The raw polymer material is first subjected to heat to melt it into a liquid state. This process is known as plasticization and typically takes place in an extruder, where the polymer is fed into a chamber, and heat and pressure are applied to melt the material. The polymer’s viscosity is controlled to ensure that it flows smoothly during processing.

3. Extrusion

Once the polymer is melted, it is passed through an extruder, where it is forced through a die to create long strands of plastic. The shape of the die determines the shape of the output, which is typically in the form of long, continuous plastic filaments.

4. Cooling and Solidification

The extruded plastic strands are then cooled to solidify the material. This is typically done using a water bath or air cooling system, depending on the type of polymer being used. The cooling process helps to solidify the plastic into a more rigid form and prepares it for cutting into granules.

5. Cutting

Once the plastic has cooled and solidified, the long strands are cut into small, uniform-sized granules using a granulator or cutting machine. The size of the granules can be adjusted based on the specific requirements of the customer or end-use application.

6. Drying

After cutting, the plastic granules are often dried to remove any residual moisture. Excess moisture can lead to defects in the final product, so drying is an essential step in the process. The drying process is typically done in drying ovens or air-drying systems.

7. Quality Control

The plastic granules are then inspected for quality. The key quality parameters include size uniformity, surface smoothness, and absence of defects such as bubbles, contaminants, or discoloration. Samples are taken from each batch and tested in a laboratory for specific physical properties, such as tensile strength, melt flow index, and heat resistance.

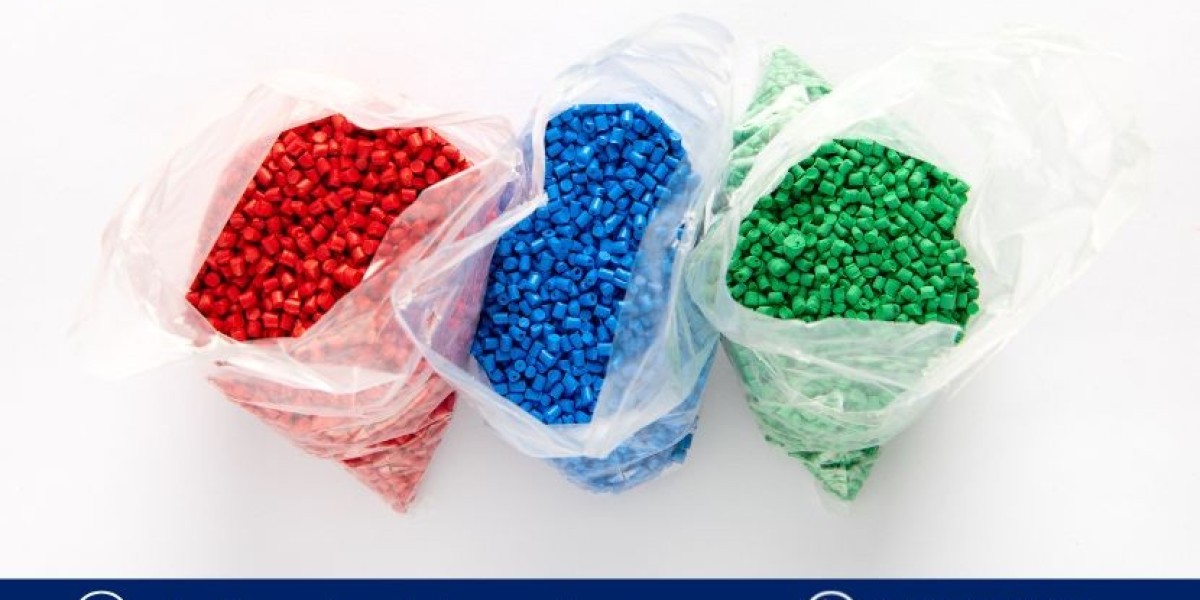

8. Packaging

Once the plastic granules pass quality control checks, they are packaged in bags or containers of various sizes for transport. These packages are labeled with relevant information, such as polymer type, batch number, and any other relevant specifications, and are then shipped to customers.

Equipment Required for Plastic Granules Manufacturing

Setting up a plastic granules manufacturing plant requires several pieces of specialized equipment to ensure efficient production. The key equipment includes:

Extruder: The machine used to melt and shape the raw plastic material into continuous strands.

Granulator: Used to cut the extruded plastic strands into small, uniform granules.

Cooling System: A water bath or air cooling system used to cool and solidify the extruded plastic strands.

Drying Equipment: Used to remove moisture from the granules before packaging.

Quality Control Instruments: Laboratory equipment for testing the mechanical and thermal properties of the granules.

Packaging Machines: For packaging the granules into bags or containers for shipment.

Investment and Operational Costs

Initial Investment

The initial investment for setting up a plastic granules manufacturing plant can be significant, involving costs for:

Land and Facility Setup: Costs for purchasing land and constructing the production facility, along with the necessary utilities.

Machinery and Equipment: Investment in extrusion lines, granulators, cooling systems, drying equipment, and quality control instruments.

Raw Materials: Sourcing initial quantities of polymer resins and additives.

Labor: Hiring skilled labor, including machine operators, quality control personnel, and administrative staff.

Ongoing Operational Costs

Ongoing costs include:

Raw Materials: Continuous procurement of polymer resins and other materials used in the production process.

Labor: Salaries for employees involved in production, quality control, and management.

Utilities: Electricity, water, and other utilities needed for running the machinery and production facility.

Packaging and Distribution: Costs related to packaging materials, shipping, and logistics.

Financial Projections and Market Analysis

A Plastic Granules Manufacturing Plant Project Report should include detailed financial projections that provide insight into the profitability and sustainability of the business. Key components of the financial projections include:

Capital Investment: A breakdown of the initial setup costs for machinery, land, and infrastructure.

Revenue Projections: Estimating potential income based on production capacity, market demand, and sales prices.

Operational Costs: Ongoing costs for raw materials, labor, utilities, and packaging.

Profitability Analysis: Calculating ROI, breakeven points, and expected profit margins.

Additionally, a market analysis should be included to identify key target markets (e.g., packaging, automotive, consumer goods) and assess the competitive landscape in the plastic granules industry.

https://www.expertmarketresearch.com/blogs/top-methanol-companies

https://www.expertmarketresearch.com/blogs/top-lpg-companies-worldwide

https://www.expertmarketresearch.com/blogs/top-labels-companies