Electric Torque Motors: A Vital Component in Modern Industrial Machinery

In the evolving landscape of industrial automation, electric torque motors have emerged as essential components across various production environments. Their precise torque control, durability, and compact design make them an ideal choice for machines that require high accuracy and reliable motion performance. As industries continue to demand smarter and more efficient systems, the role of a dependable Electric Torque Motor Supplier becomes increasingly important.

What is an Electric Torque Motor?

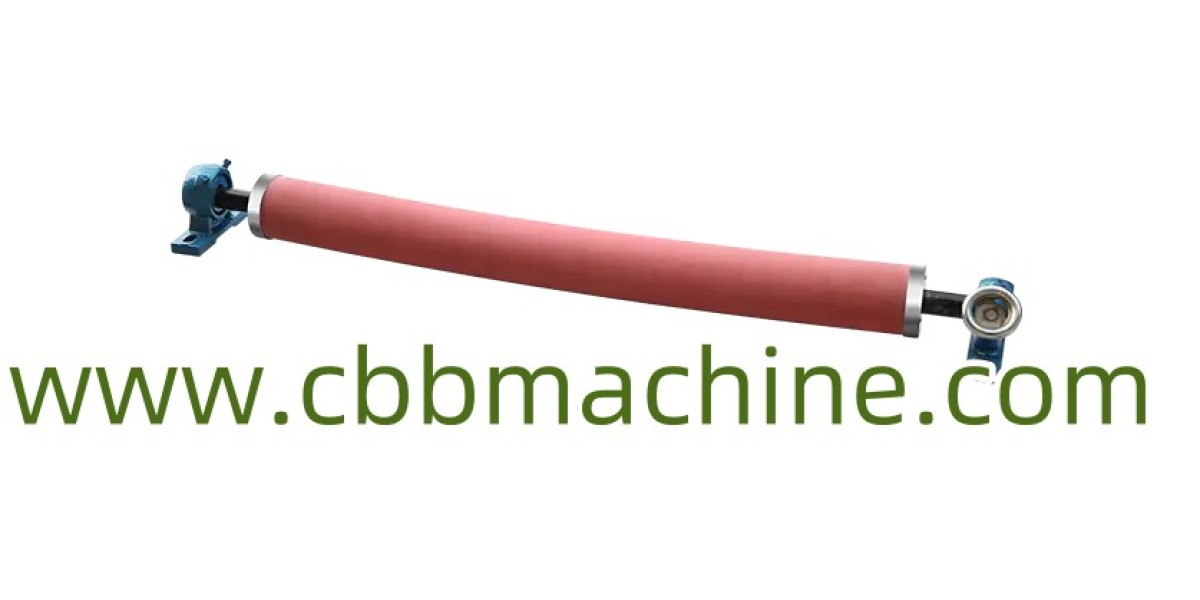

An electric torque motor is a type of direct-drive motor designed to deliver continuous torque at low speeds without the use of additional gearboxes or transmission components. These motors are particularly effective in processes where accurate torque and controlled movement are crucial—such as winding, tensioning, and positioning applications.

Compared to traditional motors, electric torque motors offer simplified mechanical design, quiet operation, and enhanced control, making them valuable in sectors like packaging, printing, film production, and textile processing.

Key Features and Advantages

Stable Torque Output

Electric torque motors maintain a consistent torque level even at zero or very low speeds. This ability is critical for applications where smooth motion and fine tension control are required.

Energy Efficiency

By supplying torque only when needed, these motors help reduce energy consumption. Their direct-drive nature minimizes power loss that typically occurs in gear systems, contributing to operational efficiency and cost savings.

Low Maintenance

Fewer moving parts mean fewer points of mechanical failure. With no need for regular gear lubrication or frequent component replacement, electric torque motors offer long-term durability and reduced downtime.

Compact Installation

The compact structure of torque motors allows for space-saving integration in machine layouts, which is a major benefit in modern production facilities where every square meter counts.

Quiet Operation

Low vibration and noise levels make torque motors well-suited for clean manufacturing environments or operations that require reduced acoustic output.

Industrial Applications

Electric torque motors are used in a wide range of industries due to their performance reliability and versatility. Some common applications include:

Packaging Lines: For unwinding and rewinding packaging films with stable tension control.

Printing Equipment: To regulate tension in paper or film feeding, ensuring high-quality print alignment.

Textile Machines: To control yarn or fabric tension in weaving and winding applications.

Labeling Machines: Where smooth, precise motor control is needed to avoid misalignment and product waste.

Food Processing Equipment: For consistent and controlled movements in wrapping and sealing systems.

In all of these areas, the effectiveness of the motor can directly impact product quality, machine longevity, and operational efficiency.

The Role of a Trusted Electric Torque Motor Supplier

A knowledgeable Electric Torque Motor Supplier plays a critical role in helping manufacturers achieve their production goals. The right supplier offers more than just hardware—they provide insight into product selection, customization options, and technical support.

Working with an experienced supplier allows manufacturers to:

Select the Right Motor Type: Matching torque requirements, size constraints, voltage compatibility, and environmental considerations.

Optimize Machine Performance: Through tailored solutions that integrate seamlessly with existing systems.

Receive Ongoing Support: Including troubleshooting, installation advice, and maintenance guidance to ensure consistent performance.

Choosing a reliable Electric Torque Motor Supplier ensures access to well-designed products, thorough documentation, and responsive customer service, all of which contribute to smoother production workflows.

Factors to Consider When Choosing a Supplier

When evaluating potential suppliers, it's important to assess their ability to meet both your technical and operational needs. Consider the following:

Experience in Your Industry: A supplier familiar with your sector will better understand your unique requirements.

Product Range and Customization: Some applications may require special motor modifications—ensure the supplier can accommodate these.

Support Services: Look for suppliers that offer technical consulting, installation guidance, and after-sales service.

Quality Standards: Ensure their motors meet recognized performance and safety standards relevant to your country or industry.

Selecting the right Electric Torque Motor Supplier is not just about acquiring components—it’s about forming a long-term partnership that supports your business’s growth and operational excellence.

The Future of Torque Motor Integration

As manufacturing continues to advance, electric torque motors are becoming increasingly integrated with digital control systems and smart automation solutions. The trend toward real-time monitoring, predictive maintenance, and adaptive machine control highlights the growing need for torque motors that are not only mechanically robust but also digitally responsive.

Suppliers who understand these emerging requirements can offer motors equipped with feedback sensors, thermal monitoring, and programmable interfaces—empowering manufacturers to adapt quickly to market demands.

Conclusion

Electric torque motors are indispensable in industries where consistent torque, low maintenance, and quiet operation are essential. Their contribution to improved precision, operational efficiency, and product quality cannot be overlooked. As the industry moves toward more connected and efficient production systems, collaborating with a skilled Electric Torque Motor Supplier ensures that businesses stay competitive and agile.